Basic Info.

| Part no. | 127-3806 Roller Group-Single Flange | Material | Bronze/Copper |

| Type | Roller | Weight | |

| Model | 307 307D 308E 307C 308D 307B 308C 307-A 307E 308E2 307E2 308E2 CR | Transport Package | Wooden Box |

| Trademark | DIRON | Origin | Luoyang City |

| HS Code | 84099991 | Production Capacity | 5000PCS/Year |

Product Details

- Item Model:127-3806 Roller Group-Single Flange

- Date First Listed:2024/11/29

- Manufacturer:Diron Parts

Product Description

- Part Number:127-3806 Roller Group-Single Flange

- Part Type:Roller Group-Single Flange

- Compatible Equipment:

MINI HYD EXCAVATOR

307 307D 308E 307C 308D 307B 308C 307-A 307E 308E2 307E2 308E2 CR

EXCAVATOR

307 307-A

COLD PLANER

PM-465

In an excavator, rollers are critical components of the undercarriage system, which supports the machine’s weight and ensures smooth movement, particularly in tracked excavators. Rollers help guide and support the tracks (also known as crawler tracks), allowing the excavator to move efficiently over rough or uneven terrain. There are typically two types of rollers in an excavator: bottom rollers (track rollers) and top rollers (carrier rollers).

Roles of Rollers in Excavators:

1. Bottom Rollers (Track Rollers):

- Location: Positioned beneath the track frame.

- Function:

- Support the entire weight of the excavator, transferring the load from the upper structure to the tracks.

- Ensure the tracks remain aligned with the track frame, preventing derailing during movement.

- Distribute the machine’s weight evenly across the tracks, enhancing stability on uneven or soft surfaces.

- Impact: Provide smooth, controlled movement, especially when operating on rough or challenging terrain.

2. Top Rollers (Carrier Rollers):

- Location: Mounted above the track frame.

- Function:

- Support the upper side of the tracks and help keep them aligned.

- Prevent the track from sagging, ensuring that it remains tight and properly tensioned.

- Impact: Maintain track alignment and tension, reducing wear and tear on the tracks and improving efficiency.

Key Roles of Rollers in Excavators:

Weight Distribution and Stability:

- Rollers help evenly distribute the excavator’s weight across the tracks, enhancing stability during digging, lifting, or traversing uneven terrain

- They prevent excessive pressure on any single part of the track, reducing ground damage and machine tipping risks.

Track Guidance and Alignment:

- Ensure that the tracks remain properly aligned and in contact with the rollers, preventing derailment or misalignment during operation.

- Allow for smooth and controlled movement, even when turning or operating on sloped surfaces.

Vibration Reduction:

- Rollers help absorb vibrations from the track as the excavator moves, providing a smoother ride for the operator and reducing wear on the undercarriage components.

Durability and Wear Resistance:

- Rollers are made from high-strength, wear-resistant materials to withstand heavy loads, continuous friction, and abrasive environments, ensuring long service life.

Maintenance of Track Tension:

- By keeping the tracks properly tensioned and aligned, rollers minimize track wear and prolong the life of both the tracks and the undercarriage components.

Common Types of Rollers in Excavators:

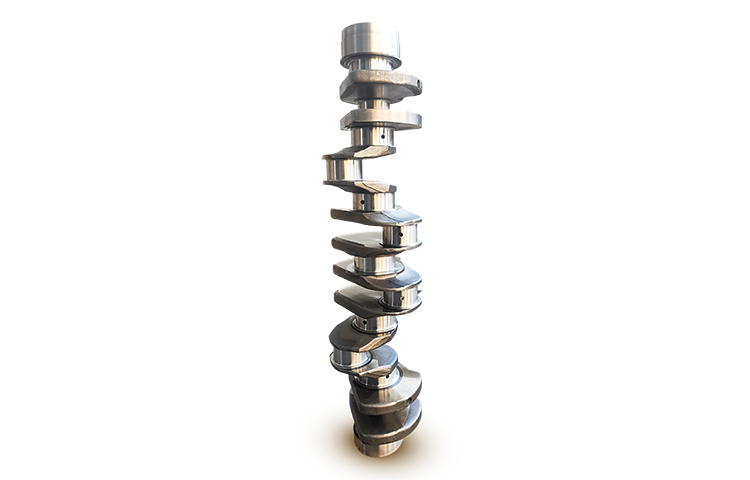

- Single Flange Rollers: Used in certain machines where minimal guidance is required.

- Double Flange Rollers: Provide more robust track guidance, commonly used in larger or heavy-duty excavators.

- Carrier Rollers (Top Rollers): Support the top portion of the tracks and ensure proper track tension.

Conclusion:

Rollers are essential for the efficient operation of an excavator’s undercarriage system. They provide critical support, maintain track alignment, distribute weight, and reduce vibration, ensuring smooth, stable, and reliable movement across various terrains. Proper maintenance of rollers is vital to prolong the life of the tracks and the excavator itself, ensuring optimal performance in demanding environments.

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: FOB

Q4. How about your delivery time?

A: Generally, it will take 20 to 30 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from

Advatange

- Advatange One

Diron Parts Group Have Its Own Factory Ensure That We Offer Better Price For Customers. Besides, Diron Corporate With Some Reliable Principal Manufacturers, So Diron Also Supply Customer Other Quality Spare Parts.

- Advatange Two

With 18 Years Experience In Manufacturing And Exporting, Diron Has A Team Of Knowledgeable Engineers, Inspectors, And Skilled Workers

- Advatange Three

The Products Export To More Than 80 Countries In America, Europe, Africa, The Middle East And So On. Reliable Quality Parts Won Trust From Valued Customers.